2025-08-05 10:38:35

In modern electrical systems, busbars play a crucial role in efficiently distributing power. Whether in power stations, industrial control panels, or electric vehicles, busbars ensure safe and reliable current flow. But how does a busbar work, and why is it so essential?

This guide answers common questions like what is busbar, what does a busbar do, and explores various types like Flexible Copper Busbar, aluminium busbar, and silver plated copper bus bar.

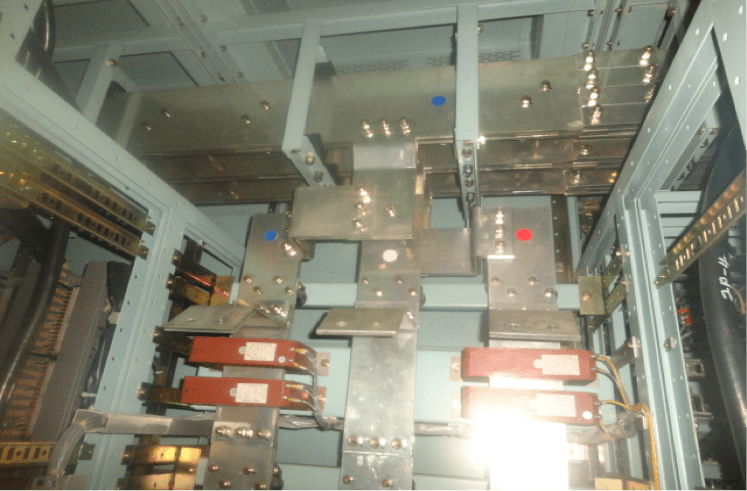

A busbar is a metallic strip or bar, usually made of copper, aluminium, or a combination of conductive materials. It serves as a central hub to collect, carry, and distribute electric current between multiple circuits. Its flat, compact shape allows it to carry large amounts of current with low resistance and better heat dissipation.

So, what is a busbar used for?

In switchgear to interconnect circuit breakers

In battery packs for connecting cells (Battery Bus Bar)

In power panels to distribute electricity

In industrial machines for modular, customizable connections (custom busbars)

The primary role of a busbar is to act as a power distribution point. Think of it as a "power highway" — it receives electricity from the power source and channels it to various outgoing lines.

A busbar:

Distributes current evenly across multiple circuits

Reduces wiring complexity compared to traditional cables

Improves reliability and safety

Supports modular and flexible power setups (see: Flexible Busbar)

Using a busbar depends on the system’s design:

Select the material based on the current load and environment. For example, a nickel plated copper bus bar is corrosion-resistant and suitable for harsh settings.

Determine the size and shape to meet current-carrying needs.

Connect devices such as circuit breakers, fuses, or batteries directly to the busbar using terminals or clamps.

Ensure insulation and proper clearance for safety.

Here’s a breakdown of common busbar types and their applications:

| Busbar Type | Description & Usage |

|---|---|

| Flexible Copper Busbar | Made from layered copper foils; ideal for vibration-sensitive or space-constrained setups |

| Aluminum Busbar | Lightweight, cost-effective; commonly used in large-scale power distribution |

| Nickel Plated Copper Bus Bar | Offers high resistance to corrosion; used in marine and industrial equipment |

| Tin Plated Copper Bus Bar | Combines conductivity with oxidation resistance; suitable for electrical panels |

| Silver Plated Copper Bus Bar | Delivers excellent conductivity; ideal for high-performance and sensitive electronics |

| Custom Bus Bars | Designed for unique system requirements; often seen in automotive, aerospace, or robotics |

| Copper Battery Bus Bar | Used in lithium-ion battery modules to connect cells and equalize current |

| Silver Plated Busbar | Enhances signal integrity; often used in communication equipment |

| Flexible Busbar | Designed for dynamic movement and compact electrical spaces |

Custom busbars are tailored to fit unique voltage, thermal, and spatial constraints. Plated busbars (e.g., tin, nickel, or silver plated copper) offer:

Enhanced surface conductivity

Better corrosion resistance

Longer life in demanding environments

They’re especially critical in sectors like renewable energy, EV battery systems, and data centers.

Understanding how a busbar works reveals its value in simplifying power distribution, enhancing safety, and reducing energy losses. Whether you're building a control panel, an EV battery pack, or an industrial energy system, choosing the right type of busbar — from aluminium busbar to flexible Copper Busbar — ensures optimal performance.

If you're looking for durable, efficient, and custom busbars, consider the material, coating, and structural flexibility to match your electrical needs.